Texas A&M Internal Combustion Senior Design Team

Formula SAE (FSAE) is a Collegiate Design Series put on by the Society of Automotive Engineers (SAE) in which teams of university students from around the world design, build, develop, and compete with small, formula-style race cars. In the multiple events held worldwide, there are classes for internal combustion, electric, and hybrid vehicles.

The rules of FSAE are far less restrictive than most racing series’ with the intention of permitting creative freedom among the teams; this results in a large variation of vehicle design at each competition. According to the regulations, the vehicle is being produced as a prototype race car for the eventual sale to the amateur weekend autocross market. This forces students to consider cost and manufacturing when building the prototype to maintain a realistic simulation for the duties of an engineer in industry.

If you would like to get in touch with the Formula Internal Combustion Team, contact us: tamufsaebusiness@gmail.com

The FSAE program at Texas A&M University offers engineering students the opportunity to be part of a team that designs, builds, tests, and ultimately competes with a small formula style race car. The program is a part of the Senior Capstone Design course. This enables students to thoroughly learn the principles of design, project management, business and engineering in order to apply them towards engineering a competitive car.

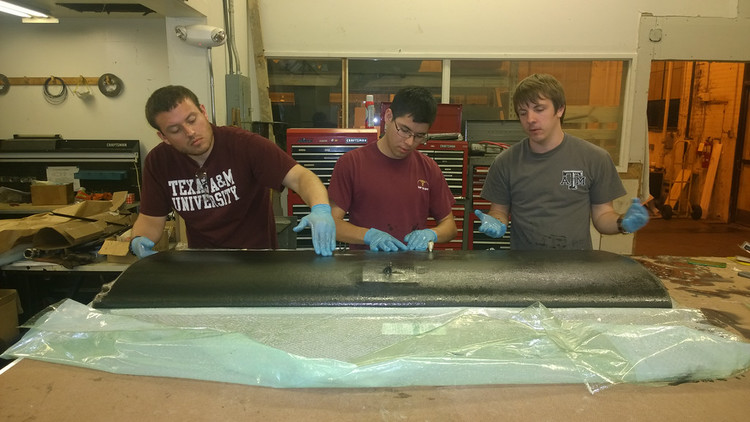

After an application process, approximately 20 senior engineering students are selected at the beginning of each Fall semester. The team designs the car during the Fall semester, and manufactures it during the Spring. Once the car is built, it is rigorously tested up until competition.

The Competition

With 1,000 points available, teams and vehicles are tested across 8 events split into two sub categories: static (325 pts) and dynamic (675 pts) events. The static events consist of Business Presentation (75), Cost (100), and Design (150), and are intended to judge the students themselves on their engineering and business skills. The dynamic events consist of Acceleration (100), Skid-pad (75), Autocross (125), Endurance (275), and Efficiency (100) with the goal of thoroughly testing the vehicles’ dynamic capabilities.

For more information regarding FSAE competition, please visit the official SAE International website.

Awards

2012 - Present: FSAE Lincoln, Nebraska, Michigan

2009 - 2011: FSAE Hybrid, New Hampshire

The Sub-Teams

The team is split into 5 basic sub-systems: Aerodynamics, Chassis, Powertrain, Electrical, and Suspension. The team also has a separate driver team who focus on developing skills in order to extract the most from the car at the competition.

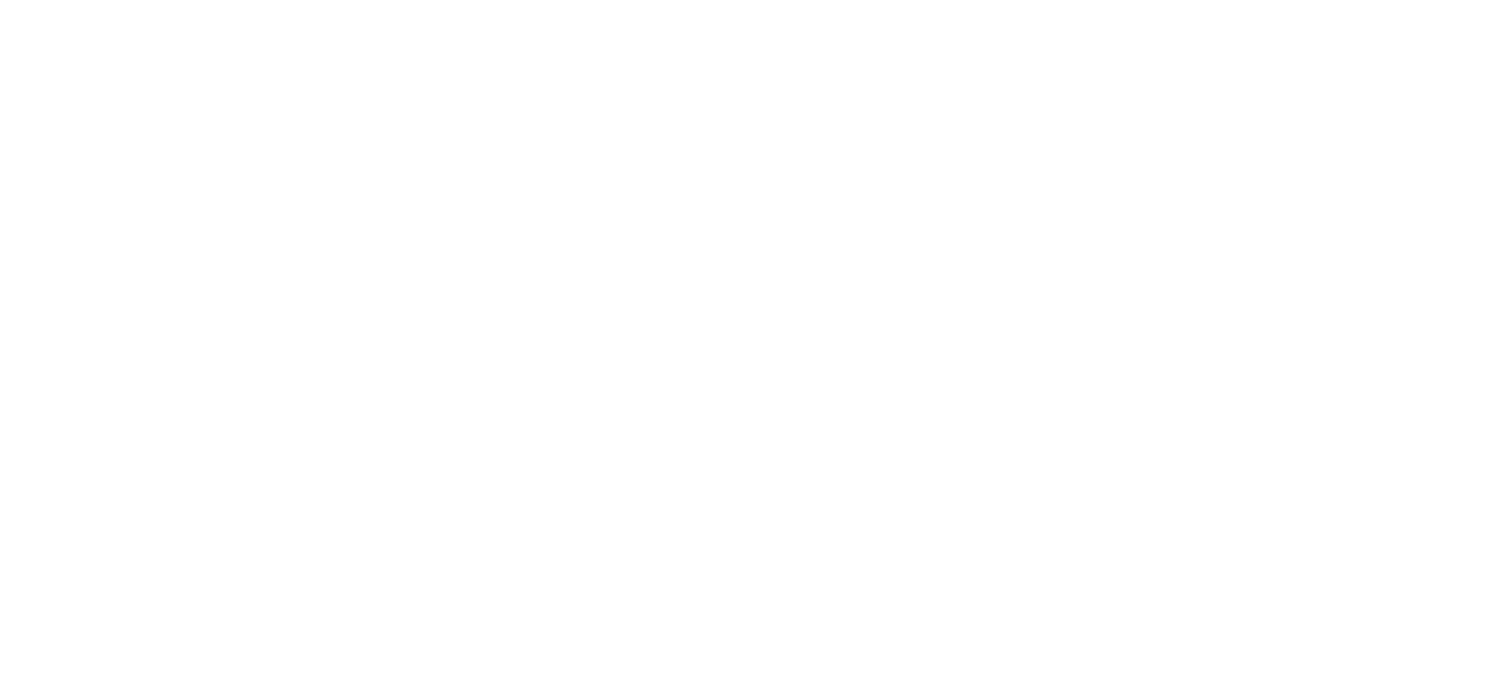

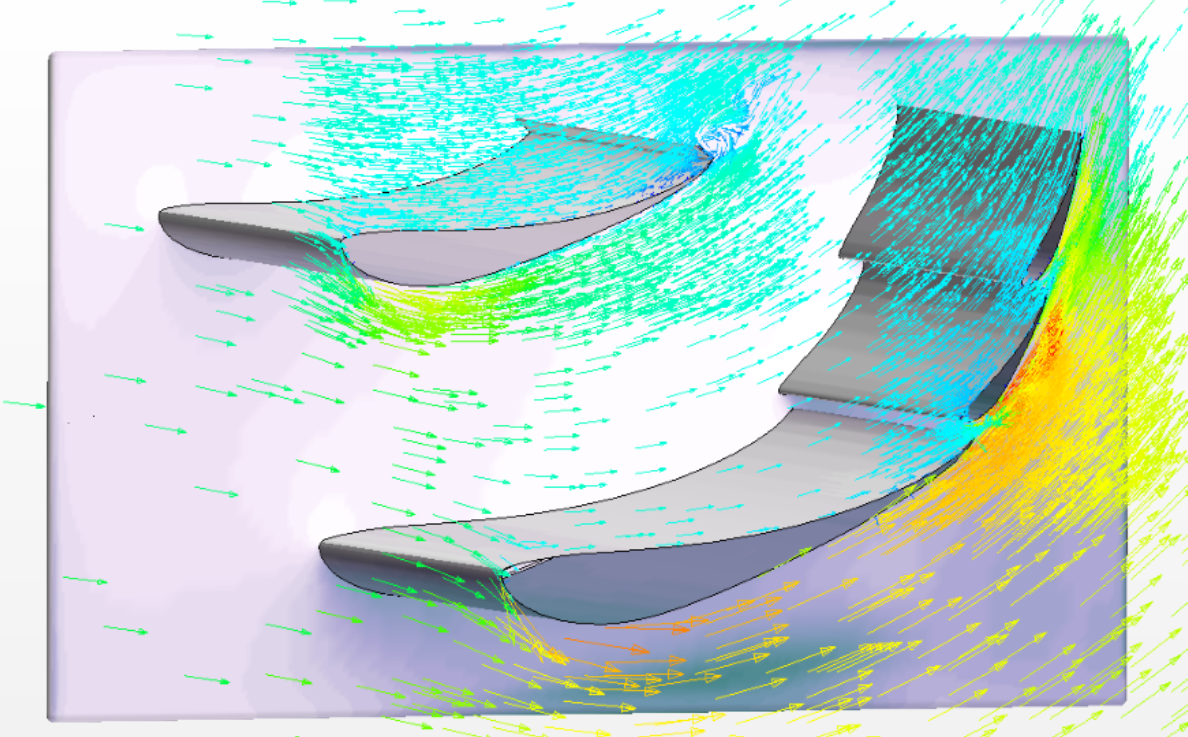

Aerodynamics

Starting in 2013, the Texas A&M began to dedicate a team solely to developing an aerodynamics package. The Aerodynamics team is responsible for developing the front and rear wings as well as any other aerodynamic devices deemed necessary. The team interfaces with the Chassis and Suspension teams to determine appropriate mounting positions, geometry, and to consider additional forces due to aerodynamic devices such as drag and downforce.

Chassis

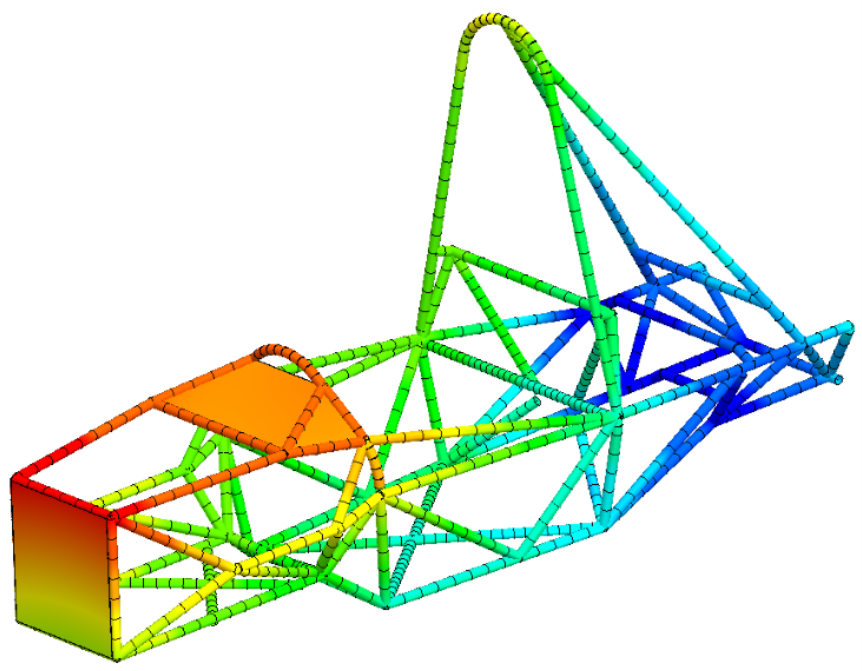

The Chassis team is responsible for designing, simulating, manufacturing and testing the system that supports and integrates all other subsystems on the car. The team ensures that the frame is structurally sound and complies with all rules and regulations including impact attenuation, tubing sizes and driver dimensions. They are also responsible for developing the safety features and driver interface which includes the seat, steering columns, pedals, harness and shifter.

Powertrain

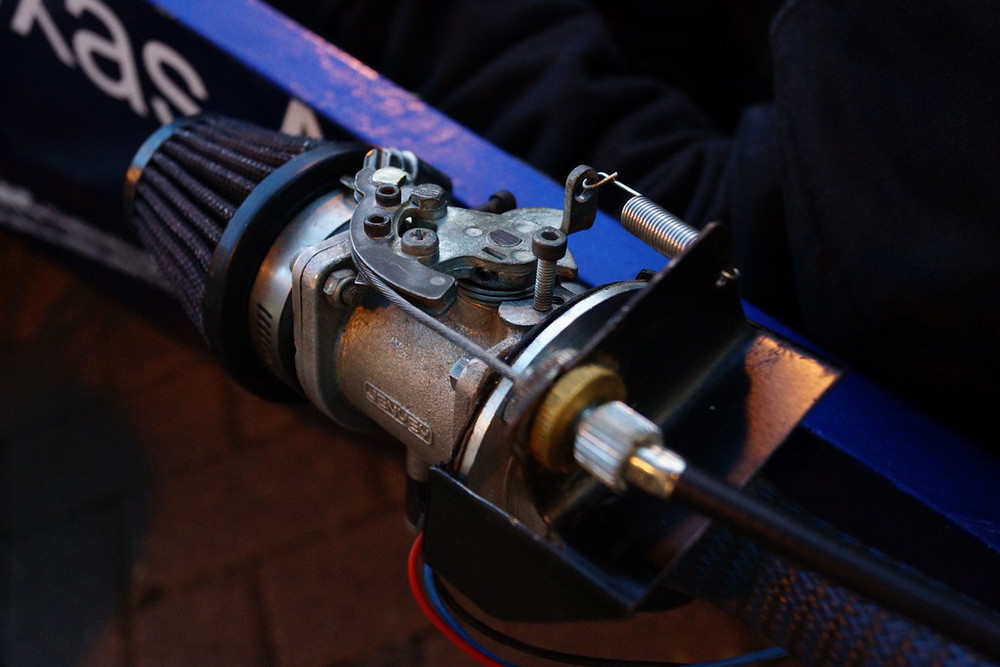

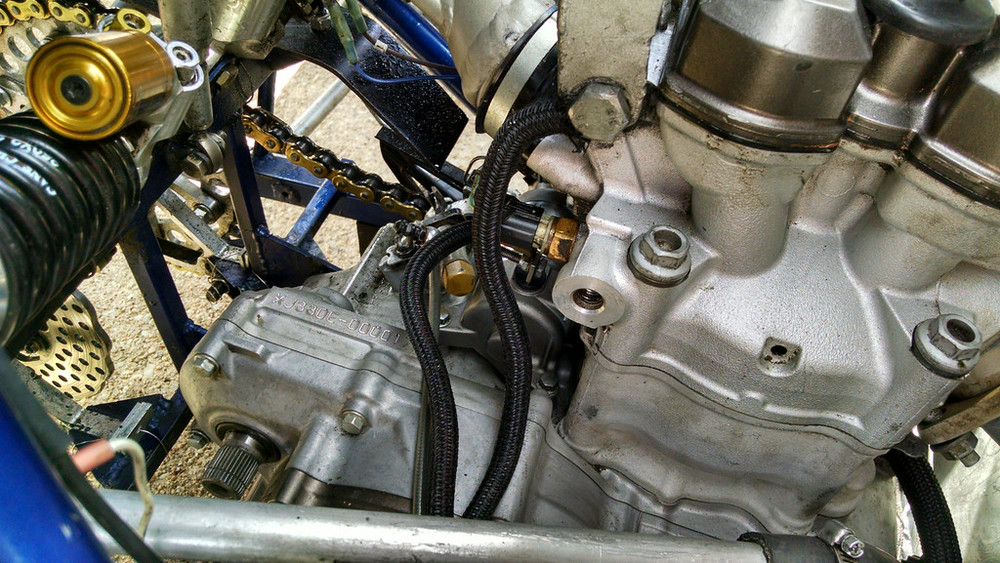

The Powertrain team is responsible for reliable and adequate propulsion of the car. The team selects an engine and must develop intake, exhaust, fuel and cooling systems in order for the engine to perform. Additionally, the team must design the drivetrain which includes the chain drive, sprockets, differential, clutch, axles, and axle joints. Engine calibration is also critical, and the team goes to great lengths in order to ensure the engine is producing maximum power in an efficient and drivable manner. Finally, the team must engineer the electrical and data acquisition systems. These systems must be thoughtfully manufactured and extremely robust. The data acquisition system must allow for quick analysis of data taken from the car in order to drive setup changes.

Suspension

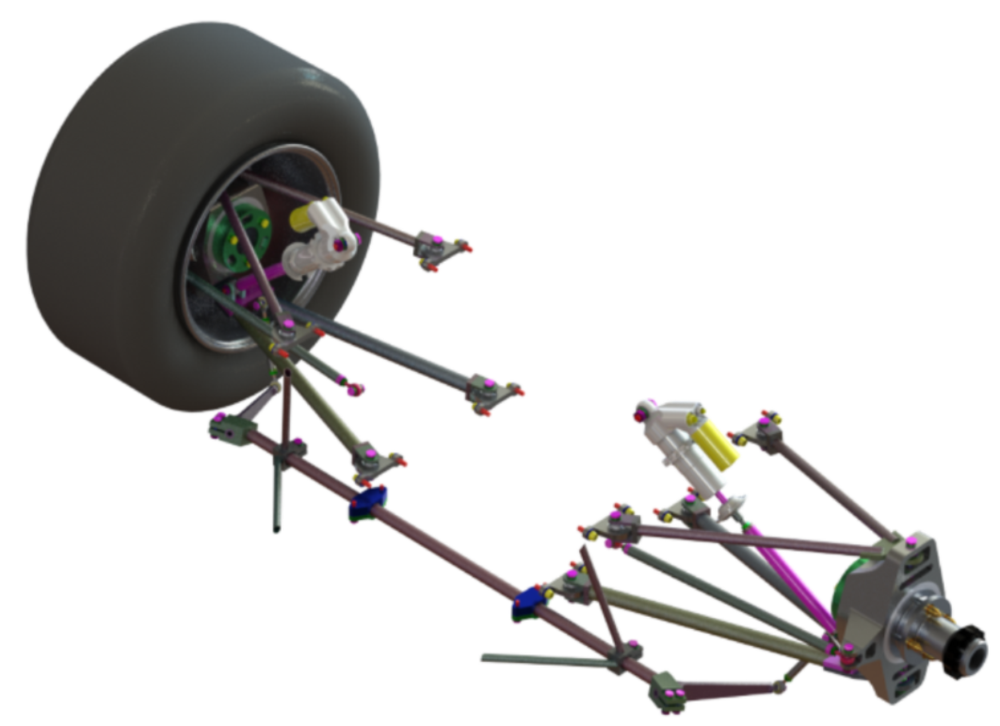

The Suspension team is responsible for the suspension system, which includes everything from the tire to the chassis attachment points. Additionally, they must design the braking and steering systems. The team's responsibilities include analyzing different types of suspension, braking and steering to decide which will be most advantageous. They evaluate data provided by the Tire Test Consortium (TTC) which allows them to make decisions about the size and compound of tire to use.

Electrical

The Electrical team is responsible for all of the electronic components and sensors that go into the car. Responsibilities of the electrical team include the dashboard, ECU, wiring, and data collection.

Drivers

The other five teams work hard to develop a safe and competitive car, but the ultimate responsibility of earning dynamic competition points lies on the shoulders of the team's drivers. Open driver tryouts are held every Fall to select new drivers, and the team often retains talented drivers if they have not yet graduated. Valuable input from experienced drivers makes it easier to design a car that may maximize dynamic performance.

Our Aggie Tradition

Each year, the FSAE team starts with a new design. Some may consider the lack of iteration in vehicle design due to the senior design designation of the project to be a weakness that prevents development of advanced vehicle technology for the Texas A&M program. However, we view this lack of iteration as our program’s major strength. Without previous designs floating around in the students’ minds, far greater creative freedom is afforded to the Texas A&M FSAE team. This creative freedom allows the students to create unique and innovative design solutions to the same set of rules from one year to the next. A prime example of this is the radical design of the 2018 car when compared to the championship-winning 2017 car; both cars are built to the same set of rules, yet are extremely different in design, aesthetic, and performance. This ability allows the engineers of Texas A&M University to find their own solutions to the set of problems presented by race car design and develop without relying on the answers found by previous students, resulting in stronger and more capable engineers at the end of their educations.

Texas A&M FSAE has a strong history of winning, despite the lack of iteration. Since the program’s rookie year in 1999 - in which Texas A&M was crowned Rookie of the Year - there have been 6 first place finishes, 2 second place finishes, 2 fifth place finishes, the Honda Award for Top Dynamic Performance in 2006 and 2007, and the Road & Track Triathlon Champions in 2004, 2005, and 2006.